Vibro Screen

Vibro Screen Specification

- Automatic

- Yes

- Power

- 10 hp Horsepower (HP)

- Voltage

- 220 v Volt (v)

- Feature

- High Performance, High Efficiency

- Color

- Multiple

- Warranty

- Yes

Vibro Screen Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Vibro Screen

Features, Uses & Application Areas

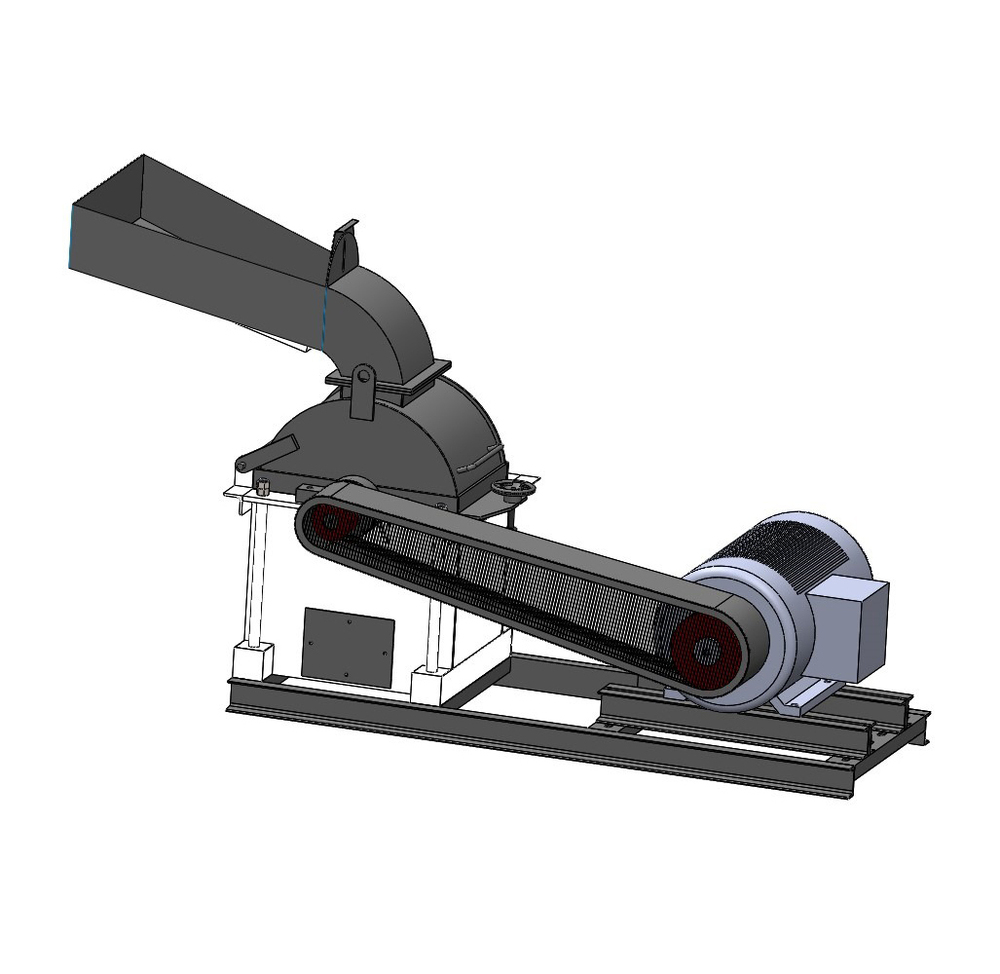

The Vibro Screen impresses with features such as automatic capability, multi-color options, and consistently high performance. Its versatility makes it ideal for separating, grading, and sifting materials in industries like pharmaceuticals, food processing, chemicals, and minerals. The machine efficiently handles granulated, powder, and slurry substances, offering unmatched accuracy in product separation. Whether in bulk material processing or precise screening tasks, it stands out as a preferred choice across various industrial applications.

Sample Policy, Supply Ability & Export Markets

The Vibro Screens sample policy allows prospective buyers to request demos before procurement. Shipped goods are meticulously packed and dispatched to ensure optimal safety during transit. With a reliable supply ability, bulk orders can be processed swiftly, and customers receive timely estimates for delivery schedules. The primary export markets include Asia, the Middle East, and Africa, establishing the Vibro Screen as a trusted choice for international clients seeking dependable industrial screening solutions.

FAQs of Vibro Screen:

Q: How does the automatic operation of the Vibro Screen enhance productivity?

A: The automatic feature reduces manual intervention, streamlines the screening process, and significantly increases throughput, making production more efficient and cost-effective.Q: What materials can be processed using the Vibro Screen?

A: The Vibro Screen can handle a wide variety of materials including powders, granules, and slurries, effectively separating, grading, or sifting based on particle size.Q: Where is the Vibro Screen commonly used?

A: This equipment is widely applied in industries such as food processing, pharmaceuticals, minerals, and chemicals for efficient material sorting and grading.Q: What is the clearance process enabled by the Vibro Screen?

A: The Vibro Screen facilitates efficient clearance by swiftly separating unwanted particles and ensuring only the desired material passes through, maintaining product quality.Q: When are shipped goods typically dispatched after order confirmation?

A: Packing and dispatch of shipped goods usually occur soon after order processing, with specific timelines provided in the delivery estimate based on order size and destination.Q: How can I procure a Vibro Screen sample for evaluation?

A: You may request a sample according to the manufacturers sample policy, which typically involves a demonstration and assessment period before final procurement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Equipments Category

Vibro Purifier

Minimum Order Quantity : 1 Piece

Color : Other, Multiple

Power : 10 hp Horsepower (HP)

Warranty : Yes

Feature : High Performance, High Efficiency

Hammer Mill

Price 105000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Other, Multiple

Power : 10 hp Horsepower (HP)

Warranty : Yes

Feature : High Performance, High Efficiency

Plan Sifter Machine

Minimum Order Quantity : 1 Piece

Color : Other, Multiple

Power : 10 hp Horsepower (HP)

Warranty : Yes

Feature : High Performance, High Efficiency

Entoleter Machine

Price 105000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Other, Multiple

Power : 7.5 Horsepower (HP)

Warranty : Yes

Feature : High Performance, High Efficiency

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry